- Home Product Power comprehensive automation monitoring backstage software Power comprehensive automation monitoring backstage software

Power comprehensive automation monitoring backstage software

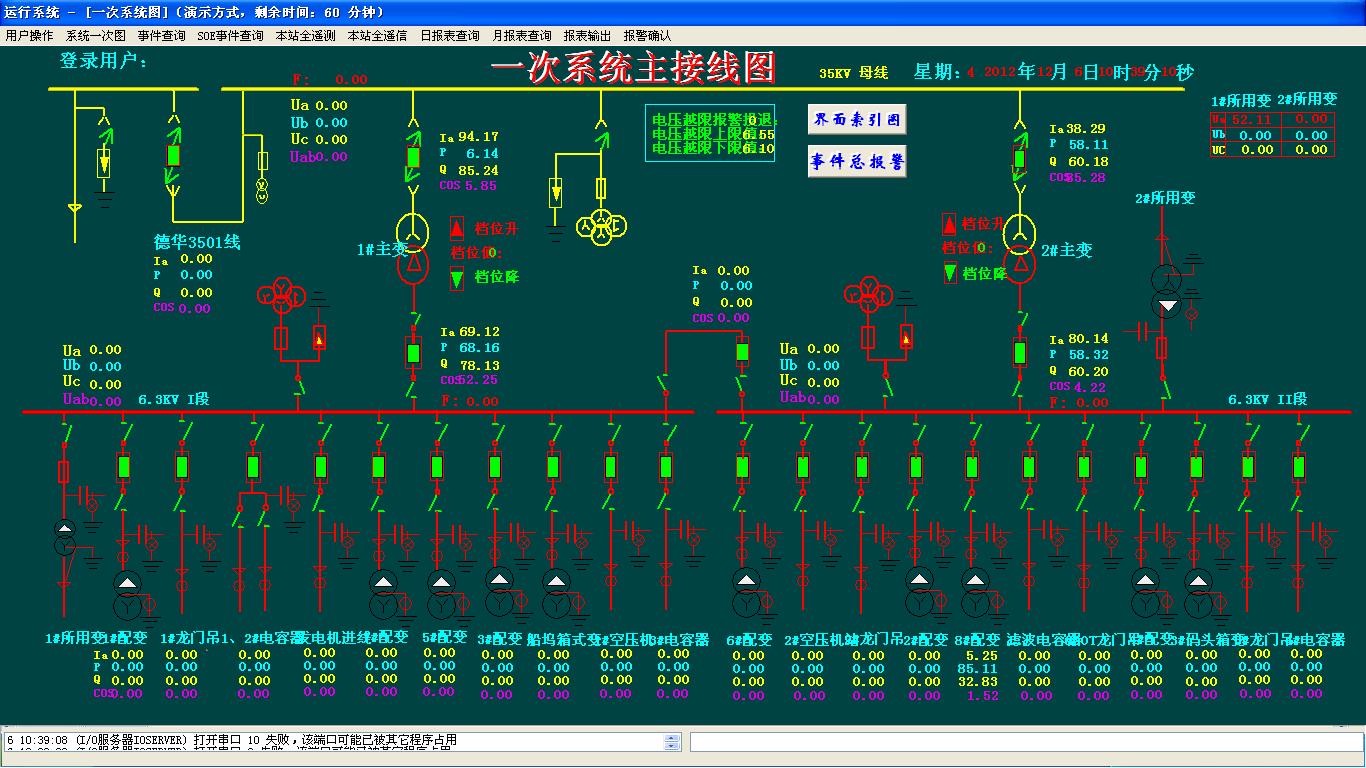

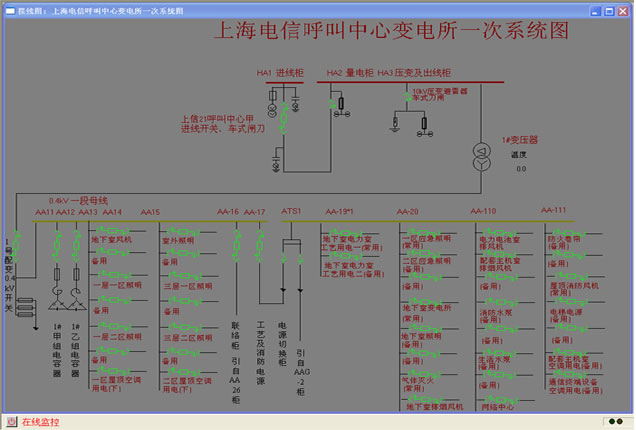

CSA8000 Monitoring System

Summary

CSA8000 monitoring system is a system platform of comprehensive multiple functions based on software and hardware technologies,referring to products of the same kind from home and abroad while taking into consideration the research and development experience on SCADA system,substation automation system and protection information management system.CSA8000 monitoring system has not only the function of basic monitoring and data collection(SCADA),but also the functions of monitoring on microcomputer protection equipment,information collection and analysis management.It can be connected to management information system(MIS)to have amore powerful of ability of information system,so it can be extensively applied to substation automation system of various voltages grades and to meet the information requirement from different management departments.CSA8000 monitoring system has broken the limitation in previous systems in terms of whole technical specification,transportability,expansibility,data consisitency,safety,real-time character.In addition,it has also exerted the convenience brought by modern computer technology in easy operation,maintenance and friendly man-machine interface.Besides,it has a broad view in design.Therefore,it can meet the various requirements from clients.

System Futures

CSA8000 monitoring system is a highly integrated applied applied platform,which combines SCADA,protection equipment management,operation order management and other functions and also open to the distant network system.

Adopting the structure of netwrk distributed system,its data and progress and be transferred dynamically to greatly exert the potential of hardware resources,improve the system reliability and be transferred dynamically to greatly exert the potential of hardware resources,inprove the system reliability and optimize the syetem performance.

Adopting the multi-system hot standby,it is automatically switched to improve the reliability of hardware.Besides, the software with multi safety security measures is used to meet safety requirements in industrial circle.

Adopting the Windows 2000/NT operation system in Microsoft,the software support system can be better connected to advanced system in the world to ensure the continuous development and maintenance of this system.

The system data is managed by transparent data management method and the database description uses object facing method while making use of the graphic man-machine interaction description to simplify the complex work and improve the maintainability of the system.

The design goal does not rely on the hardware but independent from the hardware platform,thus it can be used in various hardware platforms(including workstation of various systems,micrcocomputers and minicomputers).The industrial computeris recommended in the hardware platform.

Making use of software compilation software like 32 bits MS Visual C++ and MS Visual Basic based on Active X as well as adopting the object-facing design idea,the doftware function module can be systematically configured again to ensure the extendibility and maintainability of the system.

Based on the graphic man-machine interface,each function node computer has the operation method of unified style to be easily used.This man-manchine interface has multiple graphic picture functions to support the multi-media function at the same time.

Based on the full-duplex system,the monitoring system can be communicated with IEC60870-5-103,PLOOING and CDT stipulated station equipment to achieve various transparent,semitransparent or opaque conversion and transmission.

It can support the independent development and dynamic loading of system functions to endow the system with flexible extensibility.